What is plastic extrusion?

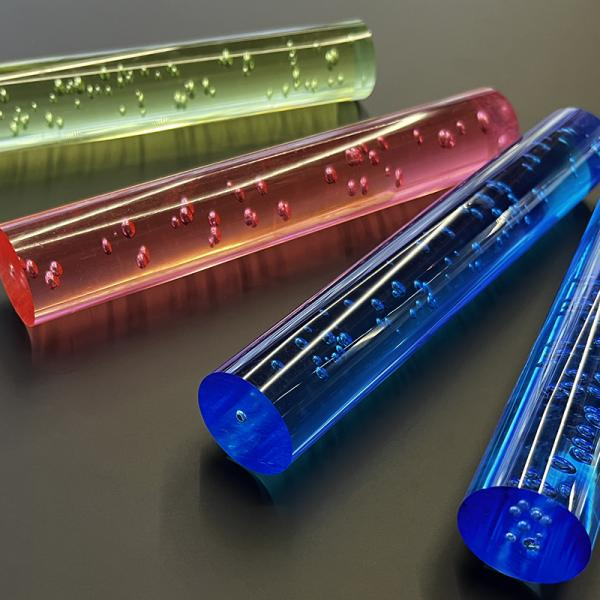

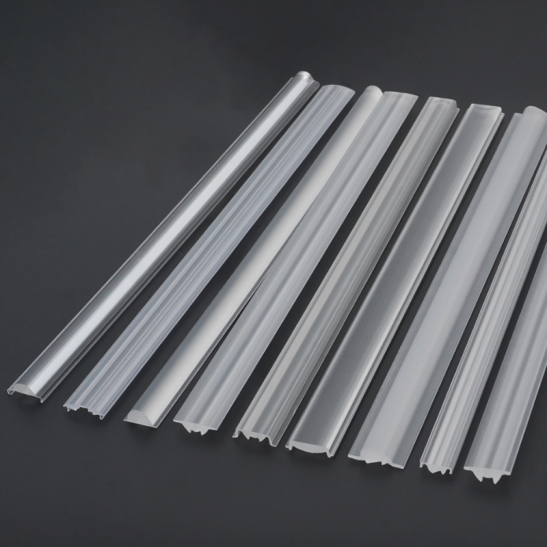

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted andformed into a continuous profile. Extrusion produces items such as pipe/tubing,weatherstripping, fencing, deck railings, window frames, plastic films and sheeting.thermoplastic coatings, and wire insulation.

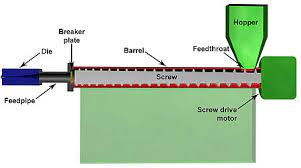

This process starts by feeding plastic material (pellets, granules, flakes or powders) from ahopper into the barrel of the extruder. The material is gradually melted by the mechanicalenergy generated by turning screws and by heaters arranged along the barrel. The moltenpolymer is then forced into a die, which shapes the polymer into a shape that hardens duringcooling.

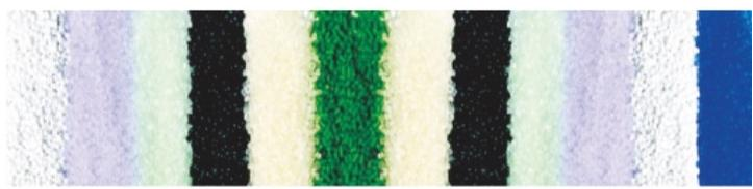

Typical extrusion materials:

Typical plastic materials that are used in extrusion include but are not limited to: polyethylene (PE), polypropylene, polyacetal, acrylic, nylon (polyamides),polystyrene,polyvinylchloride (PVC), acrylonitrile butadiene styrene (ABS) and polycarbonate.

Die types:

Main article: Die forming (plastics)

There are a variety of dies used in plastics extrusion. While there can be significant differences betweendie types and complexity, all dies allow for the continuous extrusion of polymer melt, as opposed to non:continuous processing such as injection molding.

Advantages of Plastic extrusion

Extrusion is a popular high-volume production method that offers the perfect combination of versatility, flexibility, andconsistency. Here are some of the main advantages of the extrusion process for plastic.

Cost-Efectiveness: When compared with other processes, extrusion is quite cost-effective. Generally, plastic parts aredeveloped with either injection molding service or extrusion. However, extrusion doesn't have elaborate tooling reauirements ands much simpler, resu ing in ower costs.Moreover. extrusion machines can aiso run continuousiv without any bredks.

Unparalleled Flexibility: As ong as there is a consistent cross-section, you can create any shape or profile with the plasticextrusion process.

Aiterations: Beore the coolina process. hot plastic remains auite maledble. This means that vou can easiy pertorm otheishaping operations to make sure that the final product is of the size you need.

The Main Applications of Plastic Extrusion:

As one of the main methods of creating plastic parts, the overall applications of the extrusion process are too widespread.

Plastic extrusioncanproduction of continuous lengths of plastic profiles, shapes, tubes, and other forms.