Quality assurance is non-negotiable in the production of acrylic rods, and DHT Eco-Profiles upholds the highest standards through rigorous testing processes. the company's commitment to quality and the measures taken to ensure that each acrylic rod meets or exceeds industry benchmarks.

Explore the testing protocols employed by DHT, including assessments of optical clarity, tensile strength, and resistance to environmental factors. DHT's dedication to delivering acrylic rods that not only meet aesthetic expectations but also perform reliably in various conditions.

DHT utilizes acrylic rods to enhance the aesthetics and functionality of its products. From sleek display stands to durable signage, the applications are diverse. The transparency and durability of acrylic rods make them an ideal choice for designers and manufacturers aiming for a modern and reliable aesthetic. The integration of these rods into DHT's manufacturing processes exemplifies the brand's commitment to quality and innovation.

Environmental Sustainability in Product Development:

As the demand for sustainable practices grows, DHT takes a step forward by incorporating acrylic rods with eco-friendly attributes. The recyclability of acrylic material aligns with DHT's dedication to environmental responsibility. This section explores how DHT's use of acrylic rods not only meets high-quality standards but also contributes to a more sustainable and eco-conscious approach in the industry.

DHT integrates acrylic rods strategically to support architectural elements such as canopies, railings, and partitions. This section delves into how the strength and versatility of acrylic rods enhance the structural integrity of architectural features, providing both form and function.

The transparency of acrylic rods allows for creative space division in architectural design. DHT explores innovative ways to use these rods to divide spaces without compromising the flow of natural light. From modern office layouts to contemporary residential designs, this part of the article examines how acrylic rods redefine spatial arrangements.

DHT's use of these rods ensures that architectural designs maintain their aesthetic appeal and structural integrity even in challenging outdoor environments.

Acrylic rods used by DHT contribute to the creation of hygienic surfaces in medical equipment. This section discusses how the smooth and non-porous nature of acrylic makes it easy to clean and maintain, ensuring a sterile environment in healthcare settings.

Medical equipment requires a level of durability that withstands constant use. Acrylic rods play a crucial role in enhancing the durability of DHT's medical equipment. From adjustable supports to transparent barriers, this part of the article explores how DHT prioritizes durability without compromising on functionality in the healthcare sector.

how DHT's use of acrylic rods aligns with strict healthcare standards. By meeting and often exceeding regulatory requirements, DHT ensures that its medical equipment not only serves its purpose effectively but also contributes to the overall safety and well-being of patients.

One key aspect of acrylic rods is their exceptional structural integrity. DHT engineers use these rods strategically to reinforce the structural components of various products. From supporting frameworks to reinforcing joints, the integration of acrylic rods ensures that DHT's products withstand the test of time, meeting the highest standards in durability.

DHT's acrylic rods demonstrate impressive resistance to environmental factors such as weathering and corrosion. This section explores how this resistance contributes to the longevity of DHT's products, making them suitable for a wide range of applications, from outdoor signage to industrial equipment that faces challenging environmental conditions.

Innovative Approaches to Product Development:

The utilization of acrylic rods in product development showcases DHT's commitment to innovation. By choosing materials that excel in durability, DHT stays ahead in the competitive market, offering products that not only meet but exceed customer expectations in terms of longevity and performance.

Professional, dedicated, pragmatic and innovative---Guangdong Dinghe Environmental Profile Technology Co., Ltd. has been adhering to this concept since its establishment 10 years ago. It has accumulated rich experience in the extrusion and application of plastic profiles and the development of raw materials, and provides customers with high-quality products. High-quality plastic profile products and excellent service. The main products include PC lampshades, acrylic optical lenses, plastic extruded profiles, PMMA special profiles, etc. The company currently has three major extrusion production bases and 40 extrusion production lines in Dongguan, including mold development and design center, product application development center, product mechanics and photoelectric testing laboratory, and a raw material production base, including raw material R&D center and color matching center. The company integrates design, research and development, production, sales and service.

Committed to creating a new benchmark in the "DHT" plastic profile industry. It has established long-term strategic partnerships with many well-known companies, and established joint laboratories with well-known domestic universities, specializing in the production of various types of PC, PMMA, PETG, ABS, PVC, PP, PE, POM, PA and other projects Plastic pipes, profiles and rods.

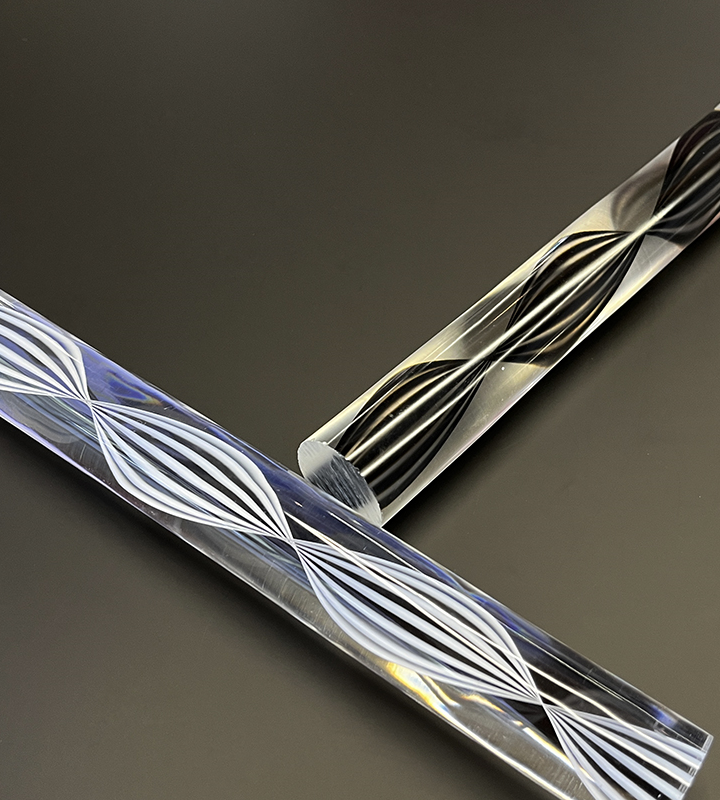

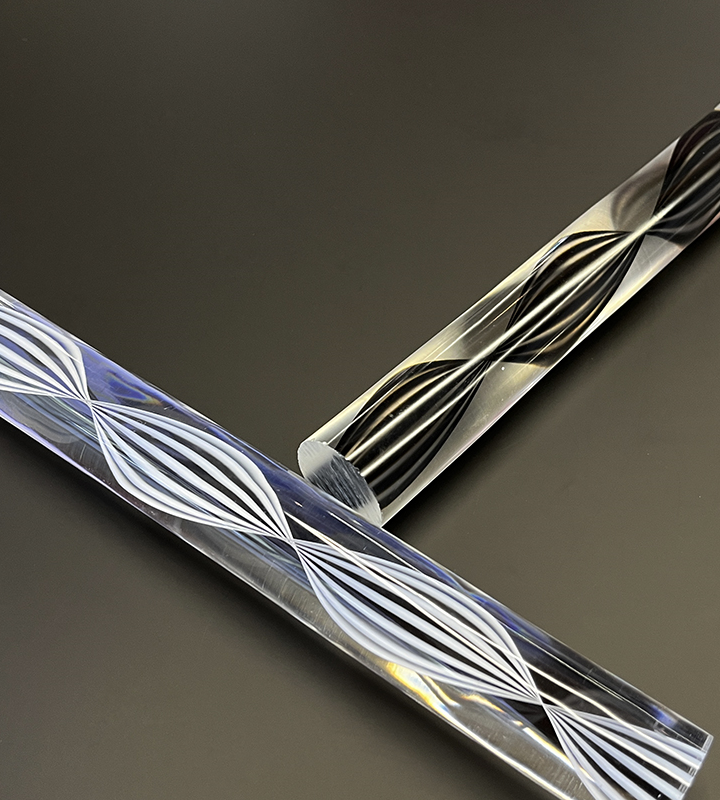

Mirror effect, exquisite workmanship, no wrinkles and no seams

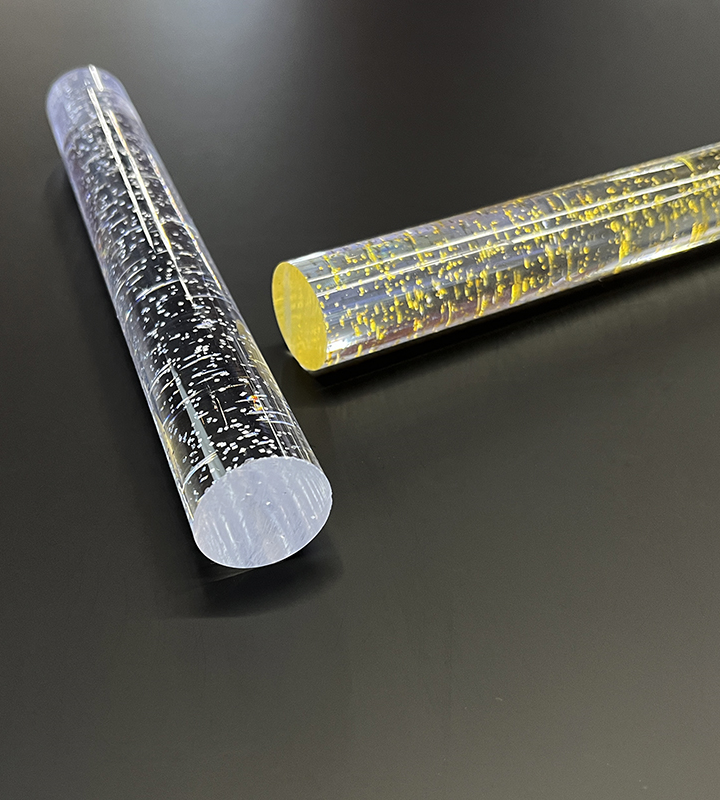

High light transmittance, good light transmittance, soft light

It can last for a long time without fading. Good quality profiles can be used for many years.

It has good heat resistance, low temperature resistance, UV resistance, and fire resistance.

DHT's acrylic rods offer exceptional clarity, UV resistance, and durability, making them ideal for high-quality displays.

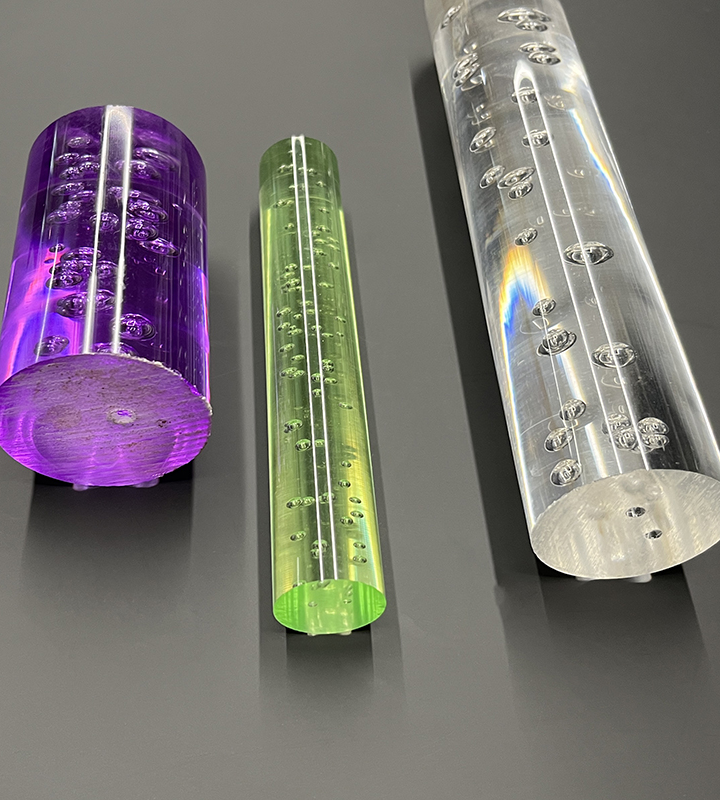

Yes, DHT offers customization options for acrylic rods to accommodate various length and diameter specifications.

DHT employs advanced manufacturing techniques to ensure the production of acrylic rods with superior optical clarity.

DHT can work to match colors based on provided samples, although exact matches may vary due to material properties.

DHT ensures careful packaging and handling procedures to minimize the risk of scratching or damage during transportation.